Testronics Model 603d

3d Backplane Profiling & Inspection System

High Reliability Detection of Compliant Press-Fit Pin Defects

|

|

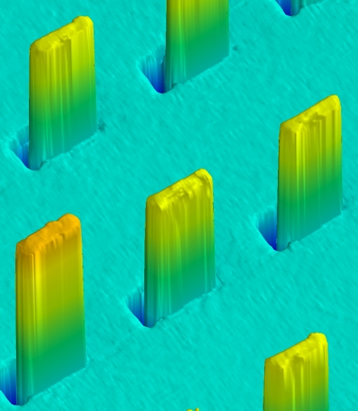

Male connector pin height & position measurements

|

Missing / crushed / bent under pins are easily identified

|

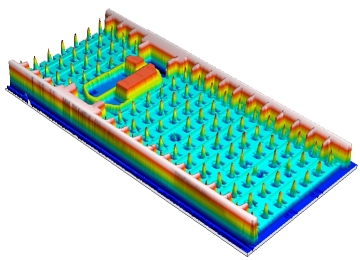

High speed, high resolution scan provides over 1,300,000 measurements per square inch |

|

A major problem in the backplane industry is detecting bent connector pin defects. The most difficult being when the pin bends underneath the shroud rather than going into the hole. Many times this defect cannot be detected electrically as the connector pin is touching the conductive annular ring of the hole, allowing electrical test to pass. Unfortunately, it is an intermittent connection and will fail later on as there is not an actual mechanical connection.

As of right now, the only method available to detect some of the pin defects is to use an X-Ray inspection system. While X-Ray does offer at least some coverage, the X-ray methodology is to acquire an image of the connector and process it using AOI algorithms. Image processing algorithms are very sophisticated and can provide stable results. However, success or failure depends on the quality of the image. The X-Ray technique works well if the image is clear and if the defect is not obscured by shadows or other features of the connector. Unfortunately, many times due to the high density of the backplane, the defect is blocked or the image is not clear enough for the AOI algorithms to reliable detect the defect. This causes the algorithms to occasionally identify defects falsely or worse, pass defects that should have been caught.

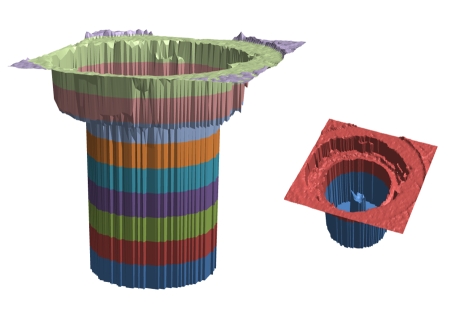

| Loaded backplane and bare board PCBA hole depth, diameter, position measurements plus debris detection | |

|

|

Back Drill depth & debris detection

|

3d profiles of bottom side hole |

Testronics Profiling System:

The Testronics system does not have the disadvantages of the X-Ray systems. This is because no images

are taken and no AOI algorithms are used. Instead, the Testronics system uses a non-contact line scanner to create a 3 dimensional map (profile) of the backplane, connector pins and connector holes. The height of each connector pin as well as its depth into the hole is mapped (profiled).

Because the Testronics system measures the actual height and depth of each pin, defects can be detected quickly and repeatably.

Defects Detected:

|

|

|

Test Backplanes up to 50" x 30", (127cm x 76cm) Scan a 10", (25cm) connector in 18 seconds Create a new backplane program in 3 - 5 hours |

Testronics 3d Backplane Profiling System |

Learn More about the Testronics Model 603d

3d Backplane Profiling System

To learn more please visit our contact page or click here: Request More Information